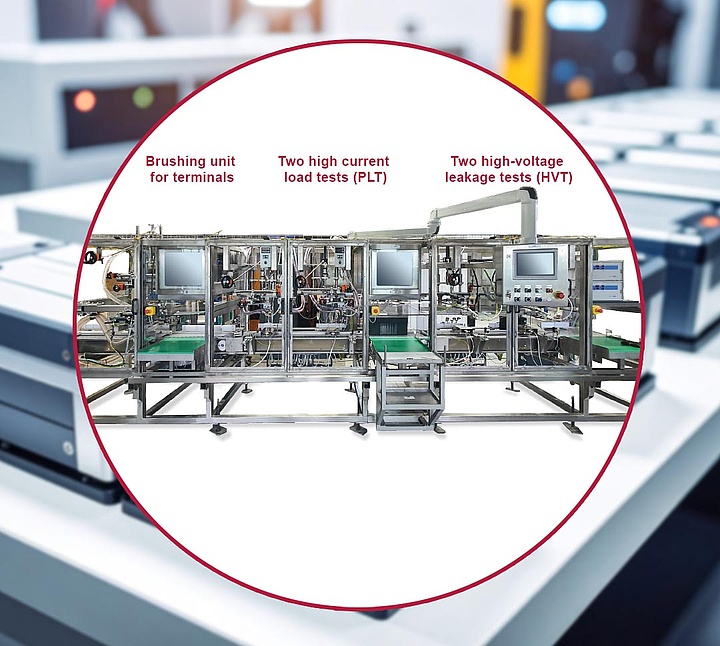

Maximum testing performance, minimum space requirement:

All test steps in one compact system

With our innovative multifunctional test machine for car and truck batteries, you can combine various test processes efficiently and space-savingly in one system. The modular design enables precise adaptation to your individual production requirements.

Choose from a wide range of extensions – from the additional lubrication station to the fully automated type changing system.

Let us talk about your test processes – together we will find the right configuration.

Example system Multifunctional test machine

* individual stations are also possible

Your benefits at a glance:

- Modular and flexible:

Combine test modules such as HRD, HVT, pole brushing and terminal lubrication as required. - Robust quality – Made in Germany:

Solid construction made from acid-resistant materials - Wide range of test devices

- Intelligent control:

Microprocessor-controlled high-voltage electronics ensure precise test results. - Integrated discharge station for N.I.O. batteries

- Clean working environment:

Powerful extraction system prevents lead dust contamination. - Time-saving test processes:

Automatic polarity switching – no conversion of the test cables necessary. - High throughput:

10 car batteries/min.

6 truck batteries/min. - Versatile in use:

Compatible with different terminal types.

Technical details:

| Battery type | all vehicles |

| Max. dimensions (W x D x H) | 8,000 x 2,000 x 2,100 mm |

| Capacity | 10 batteries/min. |

| Conveyor belt height | 850 mm +/- 50 mm |

| Conveyor belt width | 300 mm |

Brushing unit:

| Strong exhaust; standard DIN terminals / jide terminals /japanese style terminals |

PLT:

| Electrical connection (PLT) | 400 V, 50 Hz |

| Control voltage | 24 V |

| Compressed air | 6 bar |

| Material | stainless steel, acid-resistant plastic |

| Control | Siemens/Allen Bradley |

| Max. electricity discharge (PLT) | 3,000 A |

| Voltage range (PLT) | 7–14 V |

HVT:

| Testing voltage | 0–18 kV AC |

| Measuring range | 0.1–50 mA |

| Transformer capacity | 500 VA |

| Short circuit current | > 200 mA |

| Test range | weld between cover and ba |

Pütz Group – a strong association of specialists.

Our network of experts optimises your production for maximum efficiency.