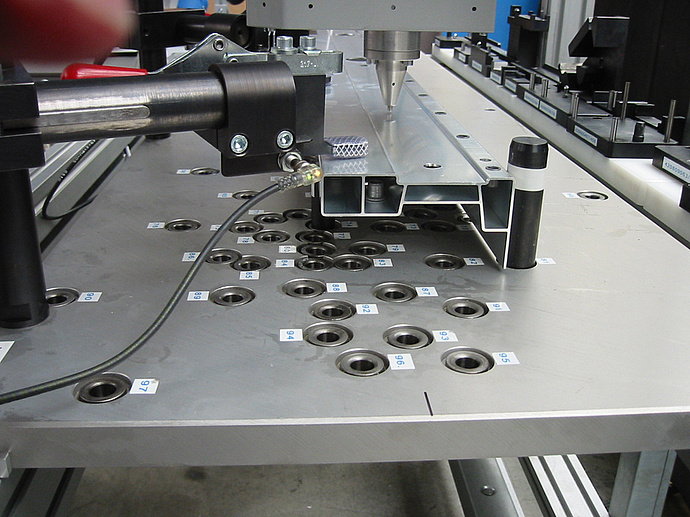

Assembly and testing workplace for aluminium strips

Function and characteristics

- The plant consists of four worktables of aluminium sectioning. These are arranged in a U shape. Each table ist designed for a specific work step.

- At the assembly workplace manually controlled pneumatic and hydraulic tools are used to assemble functional elements in pre-processed aluminium extrusion pressed sectioning. The tools are suspended individually using flexible sprung suspension means and released by the control system as the product dictates.

- Successful assembly is checked at the weighing workplace by weighing the parts before and after assembly. Each part is then labelled at the marking workplace. A flexible tensioning system ensures that items to be worked on are tensioned reproducibly.