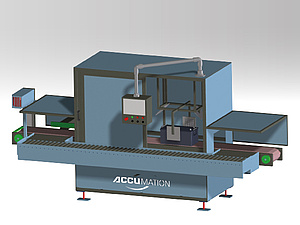

The highest test performance and lowest follow-up costs thanks to self-learning test systems

Test system for optical final car battery inspections

Your benefit:

- All defects visible to the human eye: Defects, dents, grooves, or scratches on various (including structured) surfaces

- No need for additional, expensive technical personnel The test system can be taught simply and intuitively without prior knowledge

- Time-saving, self-learning test system Inspection characteristics do not require repeated reprogramming

- Statistical evaluations of the test results for every test characteristic over freely selectable periods

- Storage and analysis of defect images

- Less waste

The highest test performance and lowest follow-up costs thanks to self-learning test systems in combination with the latest light field technology.

The know-how of two specialists – perfectly combined in this test system: Our expertise and experience as a specialist in the design and construction of machines for automotive and industrial batteries and the know-how of our Innovision sister company in camera technology.

EVERYTHING FROM A SINGLE SOURCE

Thanks to our integration into the PÜTZ GROUP and the resulting synergy effects we are able to offer you not only battery production machines but also the appropriate testing technology to test surfaces, for dimensional accuracy and completeness.